Comprehensive Guide to Clean PET Bottles for Recycling in Ethiopia

The plastic recycling business in Ethiopia is in a stage of development but still faces many problems, such as infrastructure, recycling technology, etc. Therefore, as a professional supplier of plastic recycling machine in Ethiopia, Shuliy provides the most suitable solutions for plastic recycling in Ethiopia. This post is about how to clean PET bottles for recycling in Ethiopia that meet the current market development status and needs.

The solution employs an advanced three-stage washing method, which is both energy-efficient and highly effective, effectively addressing the issues of water scarcity and exorbitant production costs in Ethiopia’s recycling market.

Step1: Remove Labels and Crush PET Bottles Before Washing

- Round bottles and flat bottles should be recycled separately due to their different physical properties. Therefore, the first step is sorting the collected PET bottles manually, and conveying plastic bottles to the de-label machine to remove labels, which prevents the mixture affect the subsequent recycling processes.

- Next, fine-tune the appropriate parameters of the plastic crusher to efficiently shred bottles into smaller fragments. The reduced flakes facilitate easier cleaning and recycling.

Step2: 3 Machines Achieve Deep Cleaning of PET Bottles

The three-stage washing method comprises the utilization of a friction washer for initial dirt removal, a sink float plastic separation for thorough impurity elimination, and ultimately a hot washing tank for complete eradication of stubborn impurities.

Friction Washing Machine

The friction washer utilizes the frictional force between the impeller and the screen, coupled with the synergistic effect of the jet water flow achieving efficient washing of PET bottle flakes, removing residual labels, sand, etc.

The nozzle design provides precise control over the water spray amount and duration, reducing excessive consumption and addressing Ethiopia’s water shortage issues effectively.

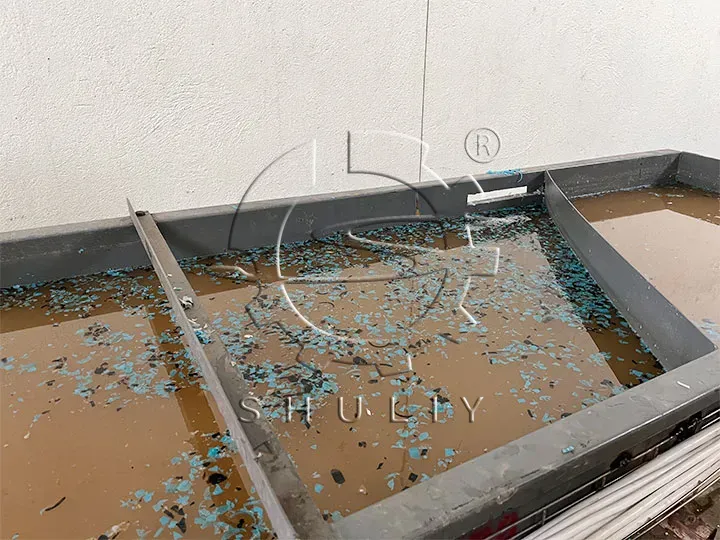

Sink Float Separation Tank

After friction washing, the washed plastic bottle scraps are conveyed to the sink float separation tank for further washing. The Tank is equipped with a water circulation system and is used to separate impurities by different densities. As the picture shows, the lighter materials float on the water’s surface and then flow out through the above holes. While heavier materials such as stones and metals sink to the bottom of the trough and are discharged. Only PET fragments are then smoothly guided into the next hot washing stage.

The Shuliy sink float plastic separation upgrade process deepens the tank body. During this process, the water flow can be controlled to effectively settle solid impurities, efficiently wash bottle flakes, and reduce the risk of pipe blockage, thereby extending equipment life and lowering maintenance costs.

Hot Washing Tank

A cylindrical hot washing tank is used for the final deep cleaning. High temperatures and the chemical reaction of cleaning agents are used to thoroughly remove stubborn grease and other contaminants. It’s typically equipped with two hot washing tanks in the PET bottle recycling line. If your raw materials are dirtier or cleaner than normal, you can add or reduce the tanks’ number.

The Shuliy hot washing tank is made of insulating materials and equipped with an efficient motor, resulting in low energy consumption and high production efficiency. Additionally, considering that Ethiopia has abundant sunlight, the Shuliy washing equipment can be powered by solar energy, greatly reducing traditional energy consumption.

Tips for Cleaning Assistance

- Please use special cleaning agents for plastic bottles to avoid damaging the recycling process.

- The temperature of hot washing is usually around 85-90 degrees Celsius.

- Try to choose a water pump or a large water tank for water supply, so that the bottle flakes can be cleaned more thoroughly.

Step3: Drying and Storing Clean PET bottle Flakes for Reuse

After multiple washing steps, use a drying machine to dewater clean PET flakes, and then store them for subsequent reproduction processes. If you have a larger output, consider adding a drying tube and a fan separator.

Why Choose Shuliy Equipment to Clean PET Bottles for Recycling in Ethiopia?

- Shuliy uses an improved process and tailors its equipment to Ethiopia’s local conditions, such as water quality and power grid, to ensure optimal performance.

- Shuliy has cooperated with several plastic packaging companies in Ethiopia, giving us rich experience in plastic bottle recycling in Ethiopia.

- We provide local personnel with operation and maintenance guidelines and answer any equipment questions.

- Shuliy offers a one-year warranty to ensure the quality of its machines.

- The design of multiple and scientific washing processes can deeply wash PET bottles, solving the difficulty of recycling dirty materials.

- Equipped with automatic systems, our machines simply operate and reduce manual costs.

In short, if you want to do plastic bottle recycling in Ethiopia, Shuliy is the best partner to assist you. Our machines are suitable for both plastic manufacturing in Ethiopia and the plastic recycling factory in Ethiopia.

Conclusion

By taking these measures, we can efficiently clean PET bottles for recycling in Ethiopia. Of course, specific solutions still need to be adjusted and optimized based on actual production conditions. Please send us:

- Your budget

- Raw materials,

- Worker numbers

- Facility information.

Our staff will provide you with more targeted advice, including layout design, the plastic recycling machine price in Ethiopia, etc. We look forward to your news and hope we can work together to reduce plastic pollution in Ethiopia!